Do you know about nano SIM card holders?

- Share

- publisher

- Moarconn

- Issue Time

- May 10,2025

Summary

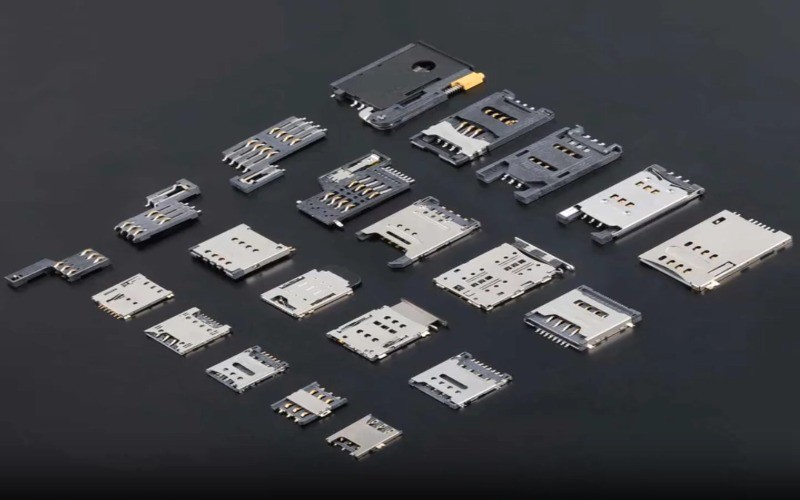

The “Nano SIM card holder” is an electronic connector used to install and secure a Nano SIM card. This is about primary functions.

Purpose of Nano SIM Card Holder

1. Physical Securing: Ensures the SIM card remains stable inside the device, preventing loosening or disconnection.

2. Electrical Connection: Uses metal contacts to communicate with the SIM card, transmitting data, power, and signals.

3. Compatibility Support: Accommodates the smallest SIM card size (12.3mm × 8.8mm × 0.67mm), meeting the design needs of slim devices.

Detailed Internal Structure

1. Metal Contacts (Pogo Pins or Spring Contacts)

Material: Typically gold-plated copper alloy for enhanced conductivity and oxidation resistance.

Quantity: 6–8 contacts, corresponding to SIM card signals (VCC, GND, CLK, I/O, RST, etc.).

Layout: Follows ISO/IEC 7816 standards to ensure precise alignment with the SIM chip.

2. Housing & Frame

Material: High-strength plastic (e.g., LCP) or metal alloy, balancing lightweight and durability.

Design: Precision-molded with guide structures for easy insertion and removal.

3. Spring Mechanism

Function: Provides counterforce to maintain tight contact between the SIM card and pins.

Durability: Supports thousands of insertion cycles (meets IPC-610 standards).

4. Dust & Moisture Protection

Rubber gaskets/Nano coatings: Prevent dust and liquid ingress (some support IP68 ratings).

5. Solder Interface

Type: Surface-mount (SMT) or through-hole (THT) soldering to the PCB.

Pinout: Must match the device’s circuit design to avoid signal interference.

Electrical Characteristics

Operating Voltage: 1.8V or 3V (auto-switching based on SIM card specs).

Data Rate: Complies with ISO/IEC 7816-3, up to 5MHz clock frequency.

Hot-Swap Protection: Some high-end holders include ESD protection to prevent static damage.

Applications

1. Smartphones: iPhone 5 & later, Android flagship models.

2. IoT Devices: 4G/5G modules, smart meters, vehicle terminals.

3. Wearables: Cellular smartwatches (e.g., Watch Cellular).

4. Industrial Equipment: Remote monitoring terminals, drone communication modules.

Technical Challenges & Solutions

1. Miniaturization: High-precision molds and automated assembly ensure tight tolerances (±0.05mm).

2. Signal Integrity: Optimized contact impedance and PCB routing to minimize EMI.

3. Environmental Resistance: Passes salt spray, high/low-temperature tests (-40°C to 85°C).

Common Issues & Maintenance

Poor Contact: Clean with alcohol swabs or replace the holder.

Insertion/Removal Failure: Check for bent slots or damaged SIM cards.

Selection Tip: Prefer reputable suppliers (e.g., Moarconn).

Evolution of SIM Card Holders

| Type | Dimensions (mm) | Introduced | Example Devices |

|--------------|-------------------|------------|--------------------------|

| Standard SIM | 25×15×0.76 | 1996 | Early feature phones |

| Micro SIM | 15×12×0.76 | 2003 | iPhone 4/4S |

| Nano SIM | 12.3×8.8×0.67 | 2012 | iPhone 5, Galaxy S6 |

This breakdown provides a comprehensive understanding of nano SIM card holders, their technical intricacies, and their critical role in modern electronics. For further details on specific models, consult manufacturer datasheets (e.g., Moarconn Connectivity’s “SIM Card Connectors Catalog”).