Do you know the echnical Challenges in the Production of Card Socket Connectors ?

- Share

- publisher

- MOARCONN

- Issue Time

- Jun 3,2025

Summary

Technical Challenges in the Production of Card Socket Connectors .

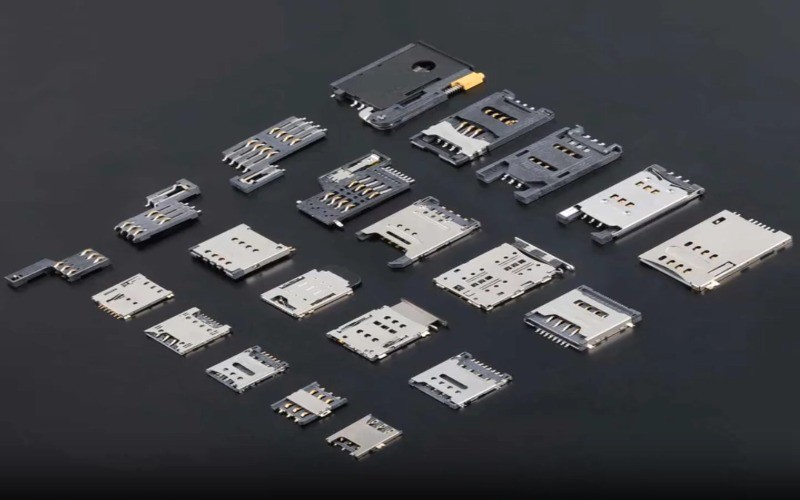

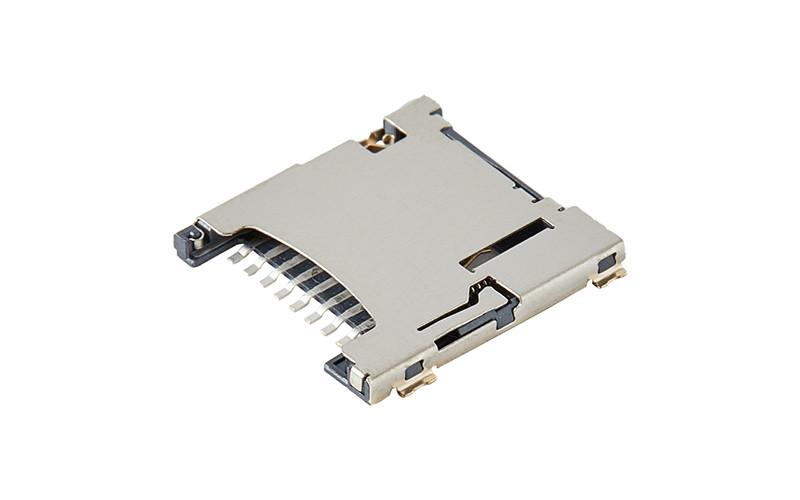

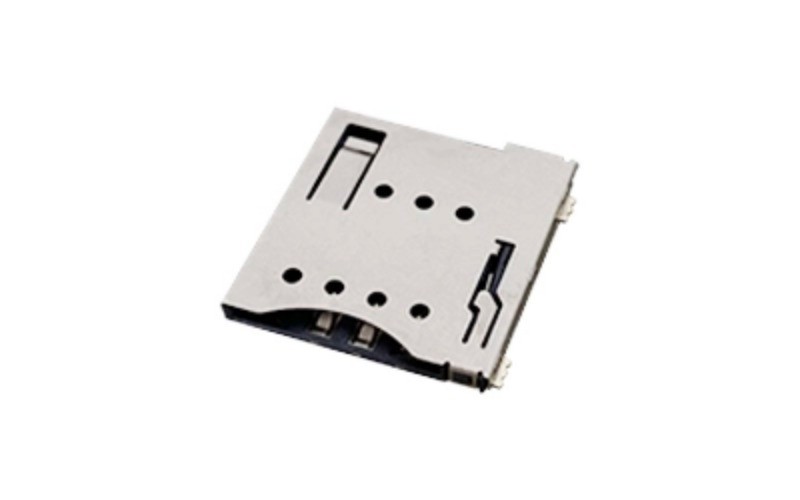

Card socket connectors (such as board-to-board, wire-to-board, FPC/FFC, SIM card sockets, memory card sockets, etc.) are compact in size but involve precision manufacturing, presenting numerous technical challenges. These difficulties directly impact the connector's performance, reliability, and yield rate. The main technical challenges include:

1. Precision Stamping and Forming

- Miniaturization and High Precision of Terminals:

As electronic devices shrink, terminal dimensions (width, thickness) become smaller, and pitch spacing becomes narrower (e.g., 0.2mm or less). This imposes extremely high demands on stamping die accuracy (micrometer level), durability, stability, and material flatness/ductility. Minor burrs, deformations, or dimensional deviations can lead to abnormal insertion/extraction forces, poor contact, or short circuits.

- Complex Shape Forming:

Contact points (spring contacts) must be precisely formed into specific geometries (e.g., cantilever beams, dual beams, crown springs) to achieve desired contact force, insertion/extraction force, normal force, and self-cleaning effects. Stress control and springback compensation during forming are critical.

- Material Selection and Treatment:

Terminal materials (e.g., phosphor bronze, beryllium copper) must balance high strength, high conductivity, elasticity, and fatigue resistance. Pre-treatment processes (heat treatment, cleaning before plating) must be strictly controlled to ensure material stability.

2. Precision Injection Molding

- Thin Walls and Complex Structures:

Insulators must accommodate multiple tiny terminals with intricate designs and ultra-thin walls (sometimes below 0.2mm). This requires extremely high mold precision and fine-tuned injection parameters (temperature, pressure, speed, time) to avoid defects like incomplete filling, flash, burrs, sink marks, or warpage.

- Material Flowability:

Engineering plastics (e.g., LCP, PPS, PBT, PA) must flow smoothly through micro-channels and cavities. Poor flow causes short shots, while excessive flow leads to flash. Precise mold design and process optimization are essential.

- Low Warpage and Dimensional Stability:

Insulator warpage directly affects terminal coplanarity, positioning accuracy, and subsequent assembly. Material selection (low shrinkage, low anisotropy), mold design (cooling system optimization), and molding parameters (holding pressure, cooling time) must be carefully controlled.

- Terminal Encapsulation and Bonding Strength:

In insert molding, plastic must tightly encapsulate terminals to ensure strong adhesion, preventing loosening or sealing issues. Terminal surface treatment (e.g., roughening, notching) and precise control of melt flow and cooling are crucial.

3. Terminal Coplanarity Control

- Micron-Level Precision:

All terminal contact points must lie within an extremely tight tolerance (typically within tens of microns) on the same plane. This is critical for reliable mating with counterpart connectors. Minor deviations in stamping, forming, molding, or assembly can accumulate, causing coplanarity failures, poor contact, or open circuits. Strict process control and 100% inline inspection are required.

4. Plating Process

- Uniformity:

Achieving consistent, dense, and defect-free plating (typically nickel underlayer + gold finish) on tiny, complex terminal surfaces is challenging. Uneven current distribution in deep holes or narrow gaps can lead to insufficient plating or burning.

- Plating Quality:

Gold plating must be pure, low-porosity, and highly wear-resistant to ensure low contact resistance, corrosion resistance, and long insertion cycles. Strict control of plating bath composition, temperature, current density, pH, and impurities is necessary.

- Micro-Gap Corrosion:

Complex terminal structures may trap plating or cleaning solutions in micro-gaps, leading to future corrosion. Effective cleaning and drying processes are essential.

- Cost and Environmental Concerns:

High gold prices demand precise thickness control while maintaining performance. Additionally, wastewater treatment from plating is both an environmental and cost challenge.

5. Assembly and Automation

- Precision Alignment:

Inserting multiple tiny terminals into corresponding micro-slots in the insulator requires ultra-high positioning accuracy (micron-level). Vision-guided systems and precision mechanical alignment are key.

- Terminal Retention Force:

Terminals must be securely locked in the insulator with sufficient retention force to withstand insertion/extraction forces or vibration. This depends on precise barb designs and insulator slot tolerances.

- Automation Efficiency and Yield:

Due to small connector sizes, high-speed, high-precision automated equipment is required. Equipment stability, feeding accuracy, and vision inspection reliability directly impact production efficiency and yield.

- Housing and Shield Assembly:

Metal shield stamping, bending, spot welding/riveting/snap-fit assembly, and plastic housing assembly must be precisely controlled for structural integrity, EMI shielding, and aesthetics.

6. Testing and Inspection

- 100% Electrical Testing:

Each connector must undergo continuity, insulation resistance (Hi-POT), and other electrical tests to ensure no shorts, opens, or insulation failures. High-speed, high-precision test probes and systems are essential.

- Micro-Contact Inspection:

Contact point geometry and surface conditions (scratches, contamination, plating defects) are critical but hard to inspect visually. High-magnification AOI or 3D inspection is often required.

- Mechanical Performance Testing:

Insertion/extraction force, retention force, and durability (mating cycles) testing require precise fixtures and sensors while maintaining production efficiency.

- High-Frequency Performance Testing:

For high-speed data connectors (e.g., USB3.x, HDMI, PCIe), expensive vector network analyzers are needed to measure S-parameters (insertion loss, return loss, crosstalk), demanding advanced equipment, fixtures, shielding, and operator expertise.

7. Environmental Reliability

- Corrosion Resistance:

Stable contact resistance must be maintained in harsh environments (sulfur, chlorine exposure), relying on plating quality and sealing design.

- Thermal Stability and Cycling:

Connectors must withstand soldering heat (especially lead-free soldering) and operational temperature fluctuations. Mismatched CTEs (coefficients of thermal expansion) between metal and plastic can cause stress, fretting wear, or intermittent contact.

- Vibration and Shock Resistance:

Particularly in automotive and industrial applications, connectors must endure vibration and shock without terminal loosening, momentary disconnection, or fatigue failure.

Conclusion:

The Core Challenges Are "Precision" and "Consistency"

- Miniaturization exponentially increases manufacturing, assembly, and inspection difficulty.

- Material performance requirements are stringent and must be tightly controlled.

- Complex, interdependent processes mean minor deviations can accumulate, leading to failures.

- High reliability and consistency are non-negotiable for electronic products.

- Cost-effective mass production must balance high precision and high yield.

Overcoming these challenges requires interdisciplinary expertise (materials science, precision mechanics, electronics, chemistry, automation), advanced equipment (high-precision molds, injection machines, stamping presses, automated assembly lines, precision inspection systems), strict process control, and continuous innovation.