Do you know what customer requirements card connectors are designed to meet?

- Share

- publisher

- MOARCONN

- Issue Time

- May 30,2025

Summary

To reliably, conveniently, and securely achieve electrical connection and physical fixation between a removable module (card) and the host device.

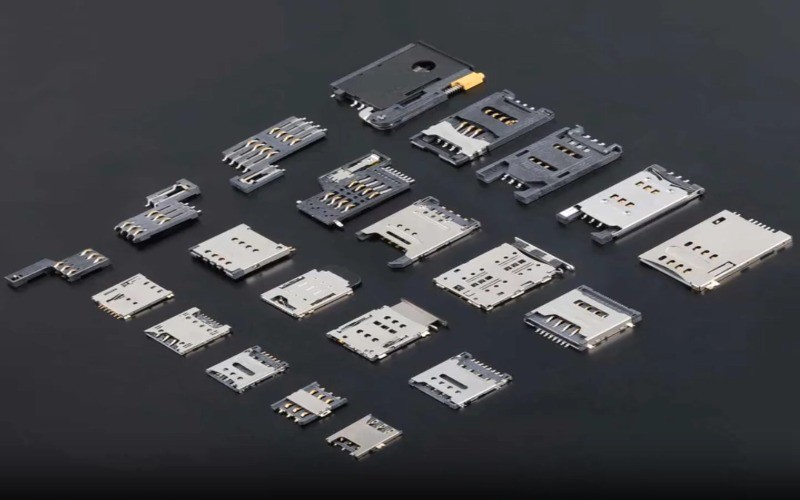

From the perspective of customer needs, card connectors (such as SIM card sockets, SD card sockets, CF card sockets, Memory Stick sockets, etc.) must meet and provide the following key points:

To reliably, conveniently, and securely achieve electrical connection and physical fixation between a removable module (card) and the host device.

Detailed Breakdown:

1. Reliable Electrical Connection:

- Low Contact Resistance: Ensures stable and efficient signal and power transmission, minimizing energy loss and signal attenuation. Customers demand stable device performance, uninterrupted data transfer, and low power consumption.

- High Current-Carrying Capacity (if applicable): For cards requiring power (e.g., high-speed memory cards, modules), the socket must safely handle the required current to avoid overheating or contact failure.

- Signal Integrity: For high-speed data transfer (e.g., UHS-II SD cards, CFexpress), the socket design (impedance matching, crosstalk suppression, shielding) must ensure signal quality and minimize bit errors. Customers need fast, error-free read/write operations.

- Stable Contact Force:The spring contacts must provide sufficient and durable pressure to maintain stable contact resistance under various conditions (vibration, shock, temperature fluctuations). Customers fear issues like "card not detected" or unstable performance due to poor contact.

2. Secure Mechanical Connection & Durability:

- Precise Alignment & Positioning: Must guide the card smoothly and accurately into place, preventing reverse or incorrect insertion that could cause damage. Customers expect foolproof operation.

- Strong Retention Force: The card must remain securely locked in place during normal use, movement, or minor drops, preventing accidental ejection or loosening. Customers worry about data loss or device failure due to card disconnection.

- High Mating Cycles: The socket must withstand frequent insertions and removals (especially in devices with swappable storage) without failure. Customers expect long-lasting durability—thousands or even tens of thousands of cycles are common requirements.

- Smooth Insertion/Ejection Feel: The insertion and ejection process (especially for self-ejecting mechanisms) should be smooth and effortless, with clear tactile feedback. A good user experience is critical.

3. Physical Protection & Space Efficiency:

- Card Protection: The socket and its integration into the device should shield the card from physical damage (bending, crushing, scratches).

- Space Savings: With the trend toward smaller, thinner devices, customers demand minimal PCB footprint and height. Ultra-thin, compact, and stacked designs are key.

- Thermal Management (if applicable): If the card or connector generates heat, the design must facilitate heat dissipation to prevent performance degradation.

4. Environmental Durability & Reliability:

- Corrosion Resistance:Contact materials (typically gold-plated or other noble metals) must resist oxidation, sulfidation, etc., especially in humid or sulfur-rich environments (e.g., industrial, automotive). Customers need reliable operation in diverse conditions.

- Temperature Resistance: Must operate within specified temperature ranges (consumer: 0–70°C, industrial: -40–85°C, automotive: even stricter) without material degradation or contact failure.

- Dust/Debris Resistance: The design should minimize ingress of dust or debris that could cause poor contact. Dust-proof covers are common. Customers want stability even in non-ideal environments.

- Vibration & Shock Resistance: For mobile, automotive, or industrial applications, the socket must endure continuous vibration and occasional shocks without loosening or breaking the connection.

5. Ease of Use & User Experience:

- Clear Labeling: The socket location and orientation should be clearly marked.

- Easy Card Removal: Ejection mechanisms (push-push, push-pull) should be user-friendly. Customers hate struggling to remove a stuck card.

- Status Indication (Optional but Useful): Some sockets integrate detection pins to signal card insertion status, displayed on the device UI.

6. Compatibility & Standards Compliance:

- Industry Standard Compliance: Dimensions, pinouts, and electrical specs must adhere to JEDEC, SD Association, PCI-SIG, etc. This ensures interoperability. Customers expect purchased cards to work seamlessly.

- Forward/Backward Compatibility: Where possible, support for older and newer card formats (e.g., SD sockets compatible with SD/SDHC/SDXC) extends device lifespan and usability.

7. Cost & Supply Chain:

- Cost-Effectiveness: While meeting performance needs, customers (especially high-volume consumer electronics manufacturers) are highly cost-sensitive. Design, materials, and manufacturing must optimize cost.

- Supply Chain Stability: Reliable suppliers are needed for long-term, high-volume production to avoid shortages. Customers demand supply chain security.

- Manufacturability & Yield:The design should facilitate automated SMT assembly and inspection, ensuring high production yield. Customers need efficient, low-defect manufacturing.

8. Safety & Compliance:

- ESD Protection: Must guard against electrostatic discharge during insertion/removal to prevent damage to the card or device circuitry. Customers need durable devices that protect data.

- Eco-Friendly Materials: Must comply with RoHS, REACH, and other environmental regulations—a basic market requirement.

- Flame Resistance: Housing materials should meet flammability ratings (e.g., UL94 V-0). Customers demand safe products.

Summary:

Customers’ core demands for card connectors are "reliable, user-friendly, durable, safe, and cost-efficient." Designers and manufacturers must deeply understand the application (consumer, industrial, automotive, medical, etc.), user habits, cost pressures, and environmental challenges to balance electrical performance, mechanical strength, durability, space constraints, usability, cost, and compliance. The ultimate goal is to provide seamless, reliable, and intuitive hot-swappable connectivity that enhances the end product's competitiveness and user experience.

Note:Priority of these requirements varies by application (e.g., smartphones vs. industrial cameras).