Do you know what role each part of a socket connector plays?

- Share

- publisher

- MOARCONN

- Issue Time

- May 27,2025

Summary

Functions and Roles of Various Components in a Socket Connector .

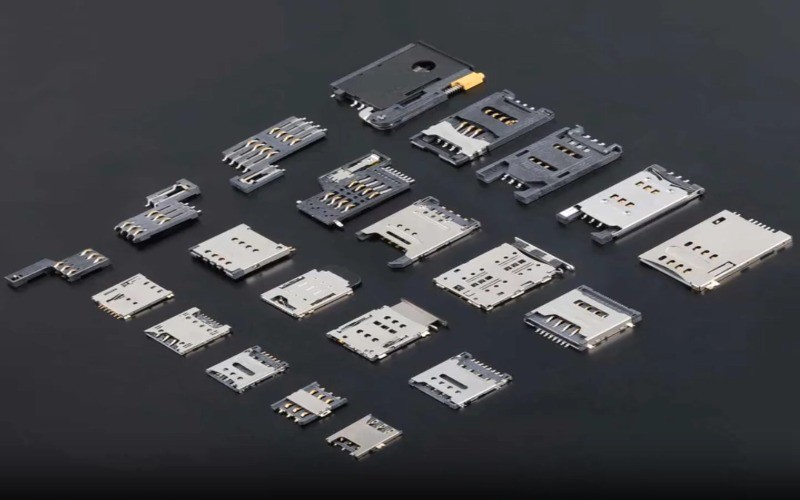

Socket connectors (such as SIM card sockets, memory card slots, etc.) are interfaces used in electronic devices to connect removable components. Their functions include signal transmission, power supply, mechanical fixation, and more. While the structural design of socket connectors varies depending on the application, their core components and functionalities are similar. Below are the main parts of a socket connector and their respective roles:

1. Housing

Functions:

- Mechanical Protection: Protects internal contacts and insulators from physical damage.

- Structural Support: Guides and aligns the plug during insertion to ensure proper positioning.

- EMI Shielding: Some high-frequency connectors feature metal shielding to reduce electromagnetic interference.

- Materials:

- Plastic (e.g., PA, PBT) or metal (aluminum alloy, stainless steel), depending on the application.

2. Contacts

- Functions:

- Electrical Conduction: Establish physical connections for signals, power, or data transmission.

- Spring Contact: Elastic design ensures stable contact and minimizes contact resistance after insertion.

- Types:

- Signal Contacts: Transmit audio, data.

- Power Contacts: Provide power or grounding (e.g., VCC and GND contacts in a SIM card socket).

- Materials:

- Copper alloys (phosphor bronze, beryllium copper) with gold/nickel/tin plating for conductivity and corrosion resistance.

3. Insulator

- Functions:

- Electrical Isolation: Prevents short circuits between different contacts

- Structural Support: Maintains precise spacing and alignment of contacts.

- Materials:

- High-temperature-resistant plastics (e.g., LCP, PPS) or ceramics (for high-frequency applications).

4. Spring Contacts

- Functions

- Contact Pressure: Provides elastic force to ensure reliable contact after insertion.

- Durability: Withstands repeated insertions (e.g., SIM card sockets must endure tens of thousands of cycles).

- Common Designs:

- Cantilever springs, pogo pins, or wave springs.

5. Guide Structure

- Functions:

- Insertion Guidance: Ensures proper plug alignment via slopes, grooves, or keying features.

- Anti-Misinsertion: Asymmetric designs prevent reverse or incorrect insertion (e.g., Micro SD card slots).

6. Locking/Eject Mechanism

- Functions:

- Mechanical Locking: Secures the plug in place using latches or springs (e.g., push-pull locking in SD card slots).

- Ejection Function: Some sockets feature a push-to-eject mechanism (e.g., SIM card trays).

7. Sealing Structure

- Functions:

- Water/Dust Resistance: Achieves IP-rated protection via rubber gaskets or molded seals - Environmental Isolation: Prevents ingress of liquids or dust.

8. Detection Switch

- Functions:

- Insertion Detection: Detects plug presence.

- Status Feedback: Sends plug-in/plug-out signals to the host device.

9. Grounding Terminal

- Functions:

- EMI Shielding: Reduces signal interference through grounding.

- Safety Protection: Dissipates static electricity or leakage current to protect circuits.

10. Shielding Layer

- Functions:

- Noise Suppression: Encases signal contacts to minimize high-frequency radiation (e.g., metal shielding in USB Type-C connectors).

- Signal Integrity: Ensures stable high-speed data transmission.

Functional Differences in Typical Applications

1. SIM Card Socket:

- Requires precise contact alignment and anti-oxidation treatment for hot-swapping and long-term reliability.

- Features write-protection detection, spring-loaded locking, and high-speed data transfer.

3. USB/Type-C Connector:

- Integrates high-speed signals, power delivery (PD protocol), and reversible insertion.

Key Performance Metrics

- Electrical Performance: Contact resistance, insulation resistance, voltage tolerance.

- Mechanical Performance: Insertion/removal force, mating cycles, shock resistance.

- Environmental Durability: Heat resistance, corrosion resistance, IP rating (dust/waterproofing).

Through the coordinated operation of these components, socket connectors achieve reliable electrical connections and mechanical fixation in compact spaces, making them critical for modular electronic device design.