Engineer’s Selection Guide: Choosing the Right TF Card Connector for Your PCB

- Share

- publisher

- MOARCONN

- Issue Time

- Sep 11,2025

Summary

TF cards (TransFlash) are widely used in smartphones, cameras, IoT devices, and industrial electronics.

Introduction

TF cards (TransFlash) are widely used in smartphones, cameras, IoT devices, and industrial electronics. Choosing the right TF card connector is crucial for device reliability and performance. This guide helps engineers select the optimal connector type and design a compatible PCB layout.

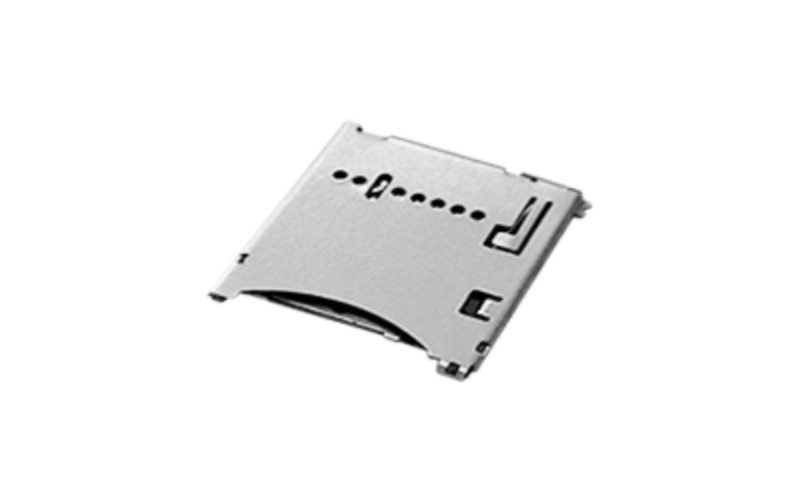

1. Understanding TF Card Connectors

TF card connectors establish the electrical connection between the card and the PCB. Common types include:

Push-Push: Push to insert and push to eject; ideal for compact consumer electronics.

Push-Pull: Push to insert, pull to eject; suitable for space-limited devices.

Hinge: Ejection via hinge mechanism; ideal for frequent card removal.

2. Key Selection Criteria

EN: Engineers should consider the following factors when selecting a TF card connector:

Mechanical Life: Number of insertion/removal cycles.

Mounting Type: Surface mount (SMT) or through-hole (DIP).

Height Profile: Connector thickness affects device form factor.

Contact Plating: Gold or other plating affects signal integrity and corrosion resistance.

Retention Force: Ensures the TF card stays securely in place.

3. PCB Layout Guidelines

EN: Proper PCB layout ensures optimal performance and reliability. Key considerations:

Signal Integrity: Keep traces short and direct; avoid sharp corners.

Ground Plane: Continuous ground under signal lines reduces noise.

Impedance Control: Maintain ~50Ω for high-speed traces.

ESD Protection: Place protection components near the connector.

4. MoarConn: Your Trusted Partner

MoarConn has over 20 years of experience in connector design and manufacturing. We offer a wide range of TF card connectors, including SD and Micro SD types, with custom solutions to meet diverse client requirements.

Customization: Tailored designs for unique applications.

Quality Assurance: Strict QC ensures reliable, high-quality products.

Technical Support: Professional support for design and application challenges.

5. Downloadable Resources

Engineers can access:

6. Contact Us

For inquiries or technical support:

Email: yezhu@kiny.com.cn

Phone: +86 18122907853

Website: www.moarconn.com