Testing, Qualification & Common Failure Modes of SD Card Connectors

- Share

- publisher

- MOARCONN

- Issue Time

- Oct 17,2025

Summary

the SD card connector serves as a critical interface between memory and the motherboard.

1. Introduction: Why SD Card Connector Reliability Matters

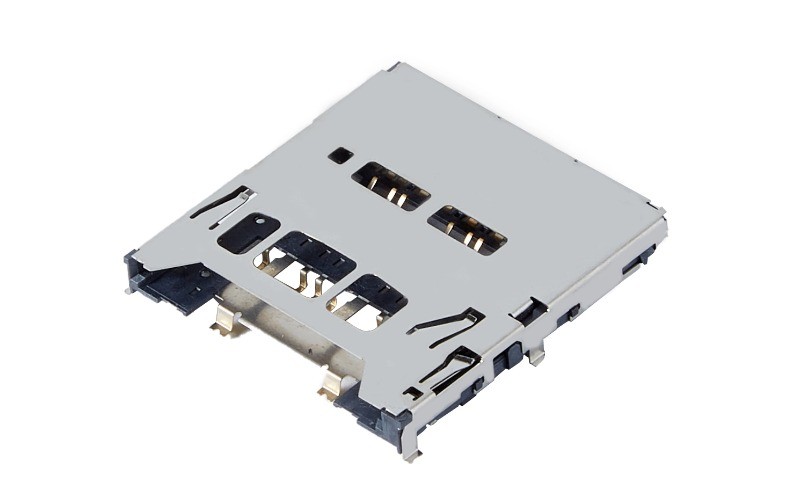

In modern electronics — from automotive infotainment systems to industrial control modules and portable consumer devices — the SD card connector serves as a critical interface between memory and the motherboard. Despite its compact size, it plays a vital role in ensuring stable, high-speed, and long-term data transmission.

At Moarconn, we understand that connector reliability is not just about connection — it’s about trust, endurance, and precision in every insertion and removal cycle.

2. Testing and Qualification Process for SD Card Connectors

To ensure reliability and compliance with standards such as IEC 60512 and JEDEC, SD card connectors undergo rigorous testing and qualification procedures to evaluate electrical and mechanical performance.

a. Mechanical Endurance Testing

Simulates 5,000–10,000 insertion/extraction cycles.

Ensures stable contact resistance and mechanical retention.

Moarconn connectors exceed 5,000+ mating cycles under laboratory validation.

b. Environmental & Thermal Testing

Includes high-temperature storage (85°C), humidity exposure, and thermal shock cycles.

Prevents deformation or fatigue under harsh working conditions.

c. Vibration & Shock Resistance

Simulates mechanical stress during transportation and device operation.

Ensures contact stability under vibration or impact.

d. Electrical Contact Resistance Test

Measures voltage drop and contact resistance under rated current.

Ensures low-loss and high-speed data transmission.

3. Common Failure Modes in SD Card Connectors

Even high-quality connectors can degrade over time. Understanding failure mechanisms helps engineers design more durable products.

a. Contact Wear & Fretting Corrosion

Repeated mating cycles cause wear on gold-plated terminals, increasing contact resistance. Micro-vibration can lead to fretting corrosion.

→ Moarconn uses gold-over-nickel plating and high-hardness copper alloys for longer contact life.

b. Housing Deformation

High temperature or prolonged stress may deform the plastic housing, causing card misalignment.

→ Moarconn uses LCP high-temperature-resistant materials to minimize deformation.

c. Solder Joint Fatigue

Thermal cycling may cause solder joint cracking or lifting.

→ Moarconn’s designs feature reinforced solder tails for improved PCB retention.

4. Moarconn’s Reliability Assurance & Testing Philosophy

At Moarconn, every SD card connector undergoes full-process quality control, combining mechanical, thermal, and environmental testing.

We uphold a zero-defect philosophy, integrating:

100% electrical continuity testing.

Batch-level reliability sampling.

This ensures that every Moarconn SD card connector used in automotive, industrial, or consumer devices maintains long-term reliability.

5. Engineering for the Future of Reliable SD Interfaces

With growing demand for high-speed, high-density data storage, connector innovation becomes essential.

Moarconn focuses on:

Contact spring design for longer insertion life.

EMI shielding for noise reduction

Custom waterproof & dustproof housings for harsh environments.

If your project needs durable, precision SD card connectors, Moarconn provides customized OEM/ODM solutions.

Visit www.moarconn.com to explore our full range of SD card connectors.

6. Conclusion

Testing and qualification form the foundation of SD card connector reliability. Understanding common failure modes and preventive engineering ensures long-lasting performance.

At Moarconn, we don’t just manufacture connectors — we engineer confidence in every connection.