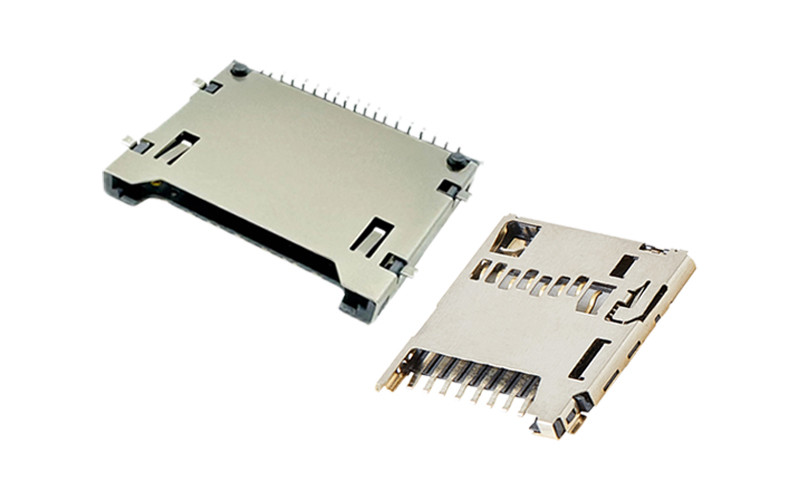

Card Connectors: The Complete Manufacturing Journey from Raw Strip to Finished Module

- Share

- publisher

- MOARCONN

- Issue Time

- Oct 9,2025

Summary

At Moarconn, we believe that manufacturing is not just repetition—it’s discipline and insight.

In the world of modern electronics, a connector is more than a component—it’s the silent bridge of trust between circuits. Each contact, each spring force, each micron of tolerance decides whether a device will endure or fail in the field.

At Moarconn, we believe that manufacturing is not just repetition—it’s discipline and insight.

Our factory in Dongguan has built its craft around one philosophy: Precision is not a slogan. It’s a culture that must be practiced every day.

1. The Origin: Choosing the Right Material Is Choosing the Future

A connector’s reliability begins long before stamping—it begins with the grain structure of the metal and the thermal stability of the resin.

We select phosphor bronze, stainless steel, and LCP/PBT engineering plastics not by price, but by how they behave under stress, temperature, and time.

Every batch entering Moarconn’s factory passes a material fingerprint check — verifying conductivity, elongation, and resilience, ensuring that the final connector can survive thousands of insertions and still perform like the first.

2. Stamping: The Art of Controlled Impact

The stamping process defines the soul of a connector.

At Moarconn, dies are not just tools—they are the factory’s handwriting. Each punch, each cut, carries the signature of decades of accumulated know-how.

Our progressive stamping dies operate at thousands of strokes per minute with ±0.01 mm tolerance, producing terminals so smooth that even a microscope finds no burr.

In connector manufacturing, stamping is not about force—it’s about respect for boundaries. Knowing how much to bend, and how much to stop.

3. Plating: Science Meets Endurance

The shine of a connector isn’t cosmetic—it’s functional armor.

Each terminal is plated with nickel, tin, or gold, depending on its application, to protect against corrosion, oxidation, and time itself.

Moarconn’s plating labs test thickness uniformity, adhesion strength, and salt-spray resistance—because endurance is not claimed; it’s proven.

4. Injection Molding: Structure Defines Identity

The housing defines how a connector feels, fits, and functions.

We use high-temperature plastics that endure soldering heat without deformation.

Our in-house mold workshop allows engineers to create custom geometries, locking mechanisms, and card-detection features for different industries.

For OEM clients, this means more than a product—it means design freedom without compromise.

5. Automated Assembly: Precision in Motion

Where machines meet patience, automation becomes art.

Our assembly lines insert, bend, and lock terminals within micron-level alignment, followed by AOI (Automated Optical Inspection) for consistency.

In mass manufacturing, precision is not one success repeated; it’s no error allowed.

6. Testing: Where Trust Becomes Measurable

Before shipment, every Moarconn connector undergoes an orchestra of tests:

5,000+ insertion/withdrawal cycles

Contact resistance & insulation testing

Vibration & drop reliability

Thermal aging & solder heat resistance

We don’t just test to pass; we test to understand.

Every data point feeds back into our design for continuous improvement.

7. Packaging & Delivery: The Final Touch of Care

The journey doesn’t end at production—it continues until the product safely lands in the client’s line.

Connectors are packaged in tape-and-reel, tray, or bulk, protected against static, dust, and impact.

In logistics, as in manufacturing, we measure reliability by predictability—and that’s what global OEMs value most.

8. Why OEM Engineers Choose Moarconn

Because Moarconn doesn’t just sell connectors.

We sell control over uncertainty.

Full in-house production

Custom design & tooling support

Rapid prototyping for R&D projects

ISO9001 & IATF16949 quality system

15+ years expertise in SIM, SD, Micro SD connectors

Moarconn isn’t a big corporation, but it’s a factory that understands engineers.

We build not for scale—but for precision, integrity, and endurance.

Conclusion: Manufacturing Is a Philosophy

From raw strip to finished module, the manufacturing of card connectors is a dialogue between metal, machine, and mind.

At Moarconn, that dialogue is guided by one principle:

Build every connector as if it were the first you ever made.

That’s how we ensure every connection—physical or human—is built to last.

Learn more at www.moarconn.com