Do you understand the SD Card Connector Selection and Application Guide?

- Share

- publisher

- Moarconn

- Issue Time

- Apr 19,2025

Summary

About SD card slot connectors,there is a detailed breakdown of core requirements, selection criteria, application scenarios, and solutions to common issues.

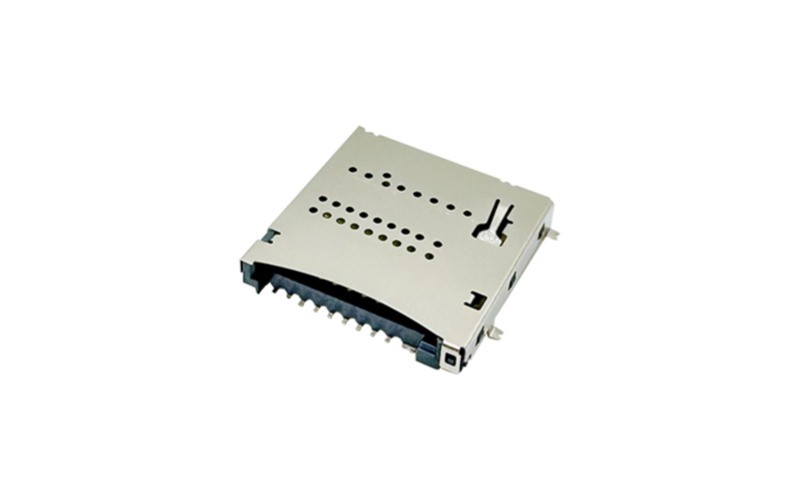

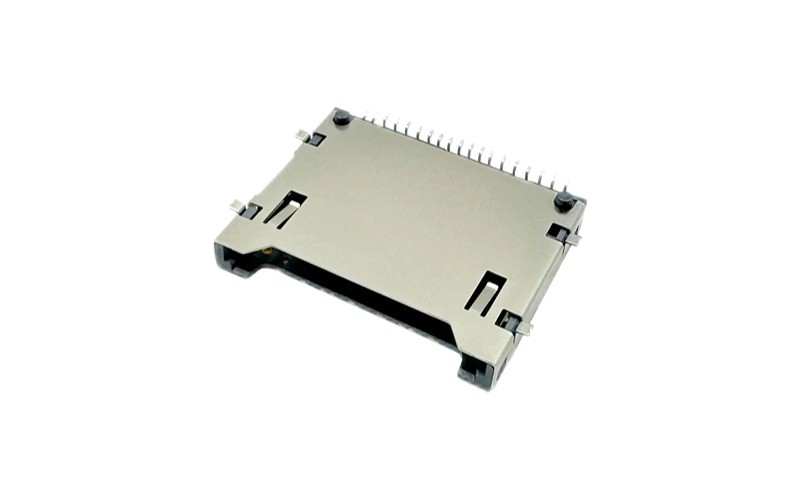

From a customer demand perspective, SD card slot connectors must be selected and applied based on comprehensive considerations of functionality, compatibility, reliability, and usage scenarios. Below is a detailed breakdown of core requirements, selection criteria, application scenarios, and solutions to common issues.

I. Core Customer Requirements Analysis

1. Functional Requirements

- Data Transfer: Support high-speed read/write (e.g., UHS-I, UHS-II standards) for HD video storage in cameras, dashcams, etc.

- Hot-Swappable: Allow card insertion/removal without power cycling for better user experience.

- **Multi-Card Compatibility**: Support SDHC, SDXC, and microSD cards (via adapters).

2. Physical Compatibility

- Size Constraints: Choose push-push (compact), push-pull (stable), or flip-latch (dustproof) types. For ultra-thin devices, select connectors ≤2mm thick.

- Orientation: Vertical or horizontal mounting to match PCB layout.

3. Environmental Reliability

- Durability: Industrial/automotive applications require high-temperature resistance (-40°C~85°C), dustproofing (IP54+), and vibration resistance.

- Durability Cycles: ≥5,000 cycles for consumer electronics; ≥10,000 cycles for industrial use.

4. Cost and Supply Chain

- Cost-Effectiveness: Plastic housings for budget devices; metal-shielded housings for premium products.

- Supply Stability: Avoid niche models prone to discontinuation.

II. Key Selection Parameters and Scenario Matching

1. Connector Type Selection

Type

Push-Push

Push-Pull

Flip-Latch

Spring Contact

Sample Content

Compact, space-saving

Tool-assisted ejection, stable

Dustproof with manual cover

Chip-level contact, ultra-thin

Sample Content

Cameras, ultra-thin laptops

Industrial controls, medical devices

Outdoor equipment, drones

Smartphones, tablets (embedded)

2. Electrical Parameters

- Signal Integrity: Impedance matching (50Ω), contact resistance (≤50mΩ) for high-speed data (e.g., 4K video).

- **Current Handling**: Must support SD card max power draw (typically ≤100mA).

3. Protection Features

- ESD Protection: Comply with IEC 61000-4-2 (±8kV contact discharge).

- Water/Dust Resistance: IP67 rating for automotive/outdoor use (e.g., rubber-sealed designs).

III. Application Scenarios and Requirements

1. Consumer Electronics (Phones, Cameras)

- Needs: Thin profile, hot-swap support, low cost.

- Solution: Spring-contact or ultra-thin push-push connectors (≤1.5mm).

2. Industrial Equipment (PLCs, Data Loggers)**

- Needs: High reliability, vibration resistance, wide temperature range.

- Solution: Full-metal housings with locking mechanisms (≥20,000 cycles).

3. Automotive Electronics (Dashcams, Infotainment)

- Needs: High-temperature tolerance (-40°C~105°C), shock resistance (AEC-Q200 compliant).

- Solution: Vertical slots with waterproof seals.

4. IoT Devices (Smart Home, Wearables)

- Needs: Miniaturization, low power.

- Solution: Embedded microSD slots (≤8×5mm).

IV. Common Issues and Solutions

1. Poor Contact

- Cause: Oxidized contacts or spring fatigue.

- Fix: Use gold-plated contacts (≥0.5μm thickness), avoid tin plating.

2. Card Jamming

- Cause: Dimensional tolerance issues or debris ingress.

- Fix: Optimize tolerances (±0.1mm), add dust covers.

3. Signal Interference

- Cause: Unshielded high-speed traces.

- Fix: Use metal-shielded connectors, isolate analog circuits on PCB.

V. Selection Process Recommendations

1. Prioritize Requirements: Rank size, speed, and protection needs.

2. Compliance Standards: Follow USB-IF (consumer) or AEC-Q200 (automotive).

3. Supplier Collaboration: Test samples (e.g., insertion force, signal integrity).

4. Long-Term Validation: Conduct thermal cycling, salt spray tests.

Summary

Customers should balance functionality, reliability, and cost based on use cases:

- Consumer Electronics: Prioritize slim designs and cost (push-push/spring-contact).

- Industrial/Automotive: Focus on durability and shielding (metal-locking designs).

- Supply Chain: Avoid proprietary models; use standardized footprints (e.g., 11.8×12.5mm).

Final tip: Share device 3D models and PCB layouts with suppliers for compatibility verification.

Dongguan Moarconn Electronics Co., Ltd. is wholeheartedly committed to serving your needs.