How to Choose the Right SD Card Connector for Your PCB — Engineer’s Selection Guide

- Share

- publisher

- MOARCONN

- Issue Time

- Sep 12,2025

Summary

Choosing the right SD card connector is a balance between electrical, mechanical, and environmental requirements.

Introduction

SD card connectors remain one of the most widely used interfaces for data storage and transfer in consumer electronics, industrial devices, and IoT systems. Selecting the right connector is critical to ensure signal integrity, mechanical durability, and compatibility with evolving standards such as SDHC, SDXC, and SD 8.0.

At Moarconn (www.moarconn.com), we specialize in the design and manufacturing of high-quality SD card connectors, Micro SD card connectors, SIM, and Nano SIM connectors. With years of expertise in precision connector engineering, we provide solutions that meet the needs of both high-volume consumer applications and demanding industrial projects.

Key Factors in Selecting an SD Card Connector

1. Form Factor & Compatibility

Ensure the connector supports the required card type: standard SD, microSD, or industrial SD cards.

For compact applications, microSD is favored, while full-size SD is still common in industrial or automotive use.

2. Electrical Performance

High-speed standards (UHS-II, SD Express, SD 8.0) demand low contact resistance and robust signal integrity.

PCB layout should consider impedance control and shielding for stable data transfer.

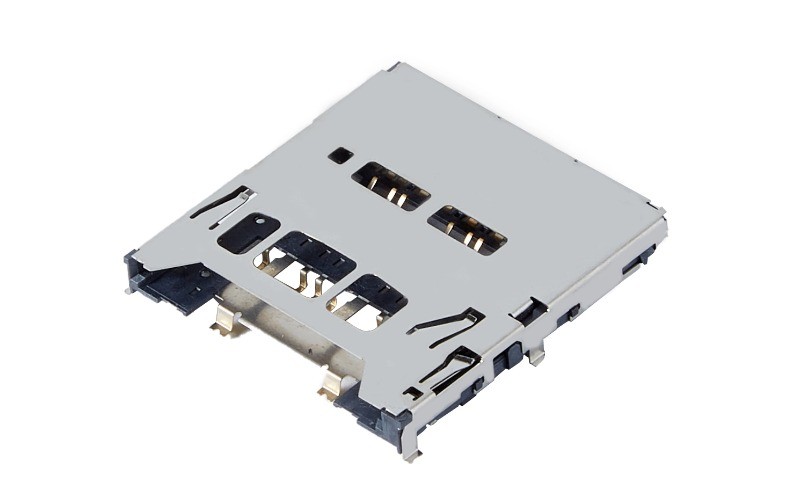

3. Mechanical Design & Durability

Engineers can choose between Push-Push, Push-Pull, or Hinged types depending on user interaction needs.

Durability matters: contacts must withstand thousands of insertion cycles without loss of performance.

4. Environmental Reliability

Industrial and IoT devices often operate in harsh environments.

Features such as dust-proof, vibration resistance, and operating temperature range (-40°C to +85°C) should be considered.

At Moarconn, our SD card connectors are tested for thermal shock, humidity, and mechanical stress, ensuring long-term reliability.

5. Mounting & Assembly Options

Choose between SMT, through-hole, or hybrid mounting depending on your PCB design.

Low-profile connectors are critical for slim consumer devices.

Moarconn offers customized height and pin layout options to optimize your design process.

Why Choose Moarconn SD Card Connectors?

Precision Manufacturing: Advanced production ensures consistent quality and reliability.

Customizable Solutions: Tailored pin configurations, profiles, and housing materials.

Global Supply Support: Stable lead times and scalable production for both prototype and mass production needs.

Trusted by Engineers: Our products are widely used in smart devices, automotive electronics, IoT gateways, and industrial equipment.

Conclusion

Choosing the right SD card connector is a balance between electrical, mechanical, and environmental requirements. By partnering with a trusted connector specialist like Moarconn, engineers can reduce design risks and accelerate time to market.

Explore more about our SD card connectors and related solutions at www.moarconn.com