Why Socket Connectors Are Essential for Card Readers? Moarconn's Advanced Technical Solutions

- Share

- publisher

- Moarconn

- Issue Time

- Apr 22,2025

Summary

As a professional manufacturer in electronic connectors, "Moarconn Electronics" explains the necessity and advantages of card socket connectors from a technical perspective.

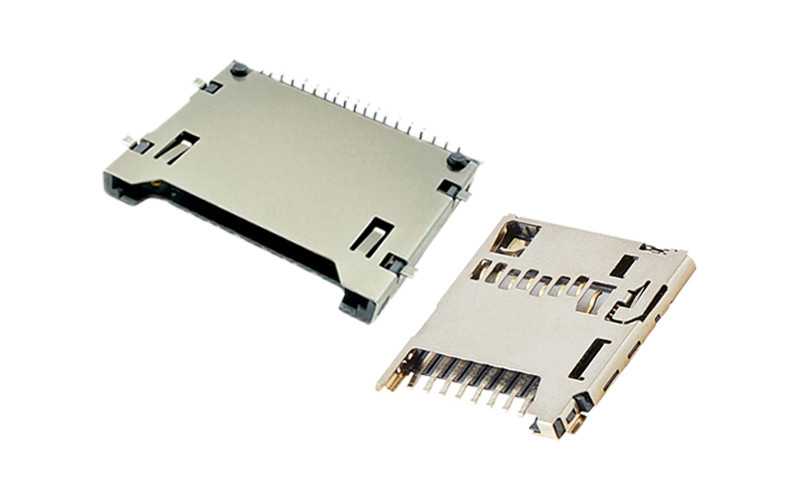

In digital applications, the performance stability of card readers heavily relies on their core component - "card socket connectors". As a professional manufacturer in electronic connectors, "Moarconn Electronics" explains the necessity and advantages of card socket connectors from a technical perspective.

I. Core Value of Card Socket Connectors

1. Precision Signal Transmission

With precision spring contacts and gold-plated terminals, card socket connectors reduce contact resistance to ≤20mΩ, ensuring stable high-speed data transfer for SD cards, SIM cards, etc. Moarconn products withstand 10,000+ insertion cycles, far exceeding industry standards.

2. Comprehensive Physical Protection

Featuring LCP flame-retardant housing with dustproof, shockproof, and 15kV ESD protection. IP67 waterproof design (proven stable operation for 5+ years in industrial cases) ensures reliability in harsh environments.

3. Flexible Compatibility

Modular design supports multiple card types (microSD, nano SIM, etc.), reducing device replacement costs. Moarconn solutions have helped customers shorten development cycles by 30%.

II. Risks of Omitting Card Socket Connectors

- Drawbacks of Direct Soldering

✅ Entire device scrapped if storage card fails;

✅ Frequent insertions risk solder joint fractures;

✅ 30% higher EMI interference risk.

- Performance Comparison

| Maintenance Cost | Replace socket/card only | Full device repair |

| Insertion Cycles | 10,000+ | Almost none |

| EMI Resistance| Shielded design | PCB-dependent |

1. Deep Customization: Supports full customization of pin counts, ejection mechanisms, etc. for ultra-thin/rugged devices;

2. Rigorous QC: 100% tested for conductivity, salt spray (48hrs), and high temp/humidity (85°C/85%RH);

3. Cost Optimization: Standard parts for fast delivery, custom solutions for joint development.

IV. Choose Moarconn to Enhance Product Competitiveness

Card socket connectors are the foundation of reader reliability. With 15 years' expertise, Moarconn serves 500+ global clients including Biyadi and Dahua, shipping 200M+ units annually to empower market success.

Contact us now for free samples & solutions!